DuFLEX panels are crucial to the light-weight and customisable design of a new breed of cruising catamaran under construction at Liquid Force Marine in Cannonvale, just a few minutes from Airlie Beach, gateway to The Whitsundays and the Great Barrier Reef.

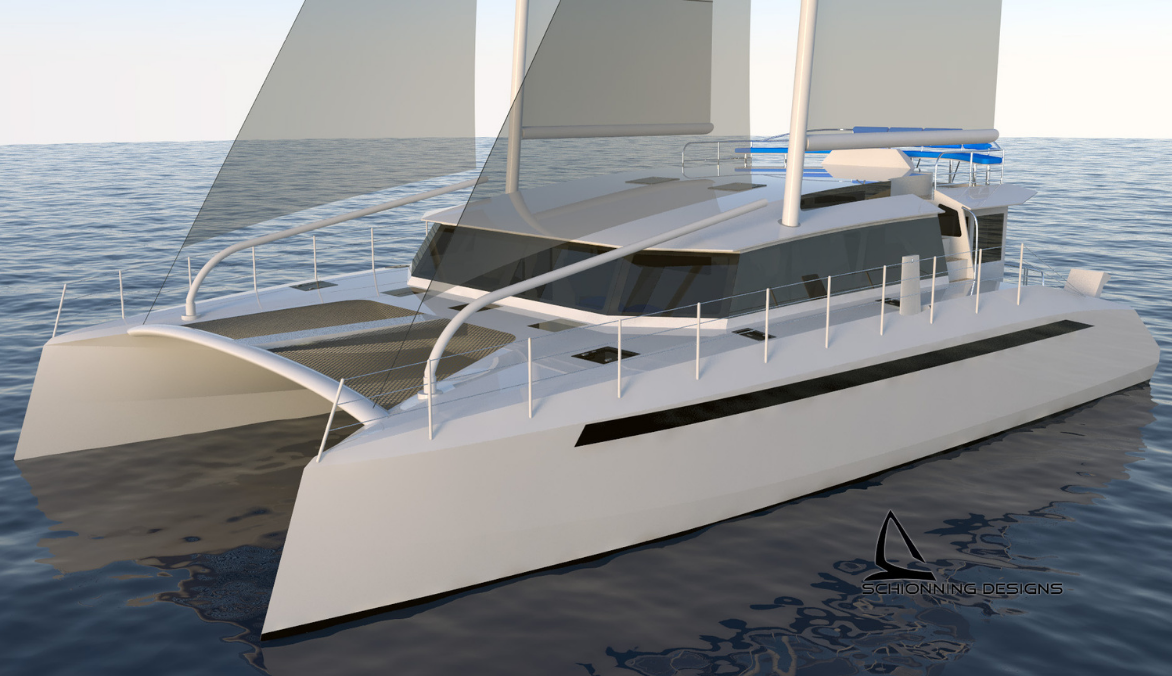

The latest Schionning Design International “Euro 1480 Bi-Plane” was custom designed by Schionning Designs International, the design studio in collaboration with the owner, Kevin Berry, who lives in Mackay. Kevin plans to enjoy his vessel with family and friends, and place the boat into charter during peak charter season in this popular cruising paradise.

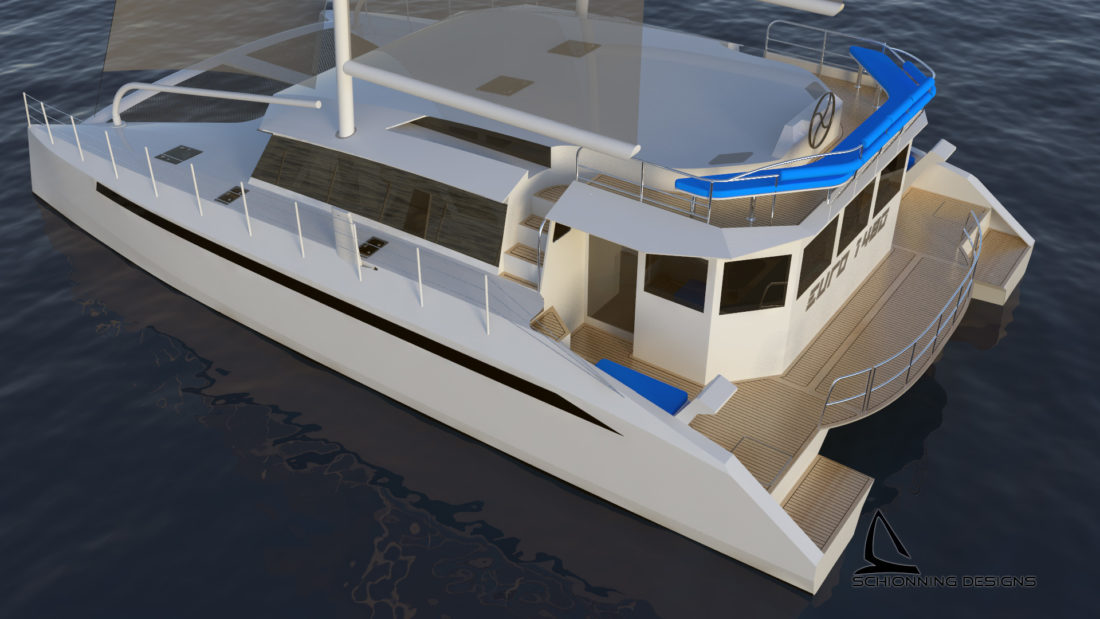

Named “Ad Astra”, the 14.9-metre multihull will be built to Survey. Its design suits commercial operations due to its simplicity, the bi-plane rig for ease of handling and the outward-situated carbon fibre masts, leaving the interior bridgedeck space unobstructed for optimal use.

“It’s definitely a step up from production vessels,” says Kevin, who drew on his own experiences over the years to create a unique platform for charter.

“It will be a performance cruiser for personal use, designed with our family in mind, but with all the features required for charter – six berths, large owner’s cabin, huge social spaces as well as plenty of privacy.”

The interior layout features a full beam main cabin with ensuite and large windows situated forward on the bridgedeck, and a walk-around galley behind leading out to a large cockpit. Two queen cabins are located belowdecks in each hull, each with ensuite, and a smaller crew berth forward.

The eco-friendly design incorporates electric motors, 6kW solar panels on the roof and a pair of lithium batteries. “The concept of alternative power deserves so much more exploration,” states Kevin.

According to boat builder and Director of Liquid Force Marine, David Morris, building a vessel to Survey and ASMA compliance adds more layers and complexities to the process. “The Schionning design is ideal for charter,” he observes. “It’s open, spacious, modern looking, stable and has a unique rig plan for more deck and cabin space.”

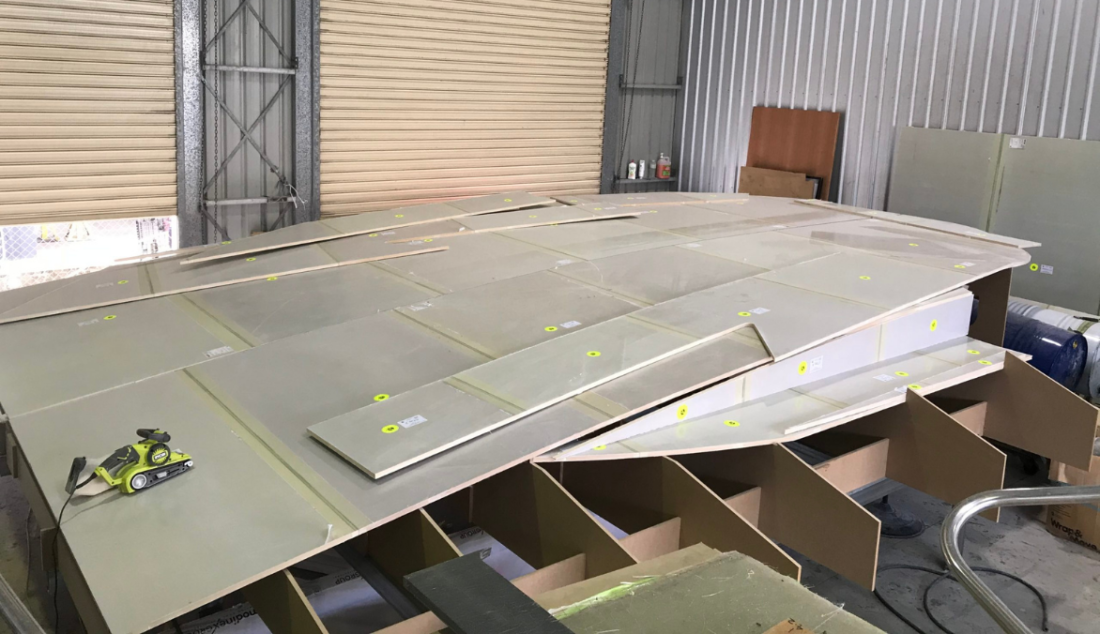

Dave has never worked with DuFLEX before and is finding it easy to work with and ideal for a custom build.

“There are many advantages to DuFLEX and the Z-Press system – it’s quick, easy to handle, exact. The CNC cut panels are very impressive. It’s a very efficient method for boat building, saving time and waste.”

The Euro 80 was speced with DuFLEX/foam panels. Depending on the part, various thicknesses of Divinycell H80 and H130 foam cores and a combination of high strength E-fibreglass in various configurations. Divinycell Foams have been the leading choice for the Marine industry worldwide for more than 30 years and provide an excellent combination of mechanical properties with low weight.

To streamline the composite panel joining process, ATL Composites has developed the proprietary Z-Press. The press applies heat and pressure to cure the epoxy adhesive on the Z-Joints. As per the joining video on this link https://www.duflex.com.au/services/joining-the-panels/ Dave and his team used Techniglue R60 Structural Adhesive in cartridges for joining the DuFLEX panels, a quick and clean process that saves time, wastage of materials and ensures an excellent bond.

Additional reinforcing is being supplied by ATL Composites including E-Fibreglass taping and carbon reinforcements. The Euro 1480 will be laminated with KINETIX R246TX with a combination of hardeners to offer options for cure and working times, and of course WEST SYSTEM epoxy and powder modifiers for all bonding, coving, filleting and fairing for the project.

With 30 years’ marine industry experience, Dave began his career in Sydney as a sailmaker and went on to professional international yacht racing. Dave is a Marine Surveyor and runs Liquid Force Marine with business partner, Brett Diessel.

For this project, Dave heads up a team of three boat builders, and will eventually bring on four additional labourers once construction begins in earnest.

The project began in February and is scheduled to be completed late next year and on-water by Christmas 2022.

ATL Composites and Schionning Designs International have had a long-standing relationship since the 1980’s and hundreds of Schionning catamarans have been built through the years using DuFLEX, and in the earlier days strip planked with DuraKore with long-lasting performance.