More at www.atlcomposites.com

vdL Composites at METS 2023

Posted on October 26, 2023

ATL Composites heads to METS 2023

Posted on September 4, 2023

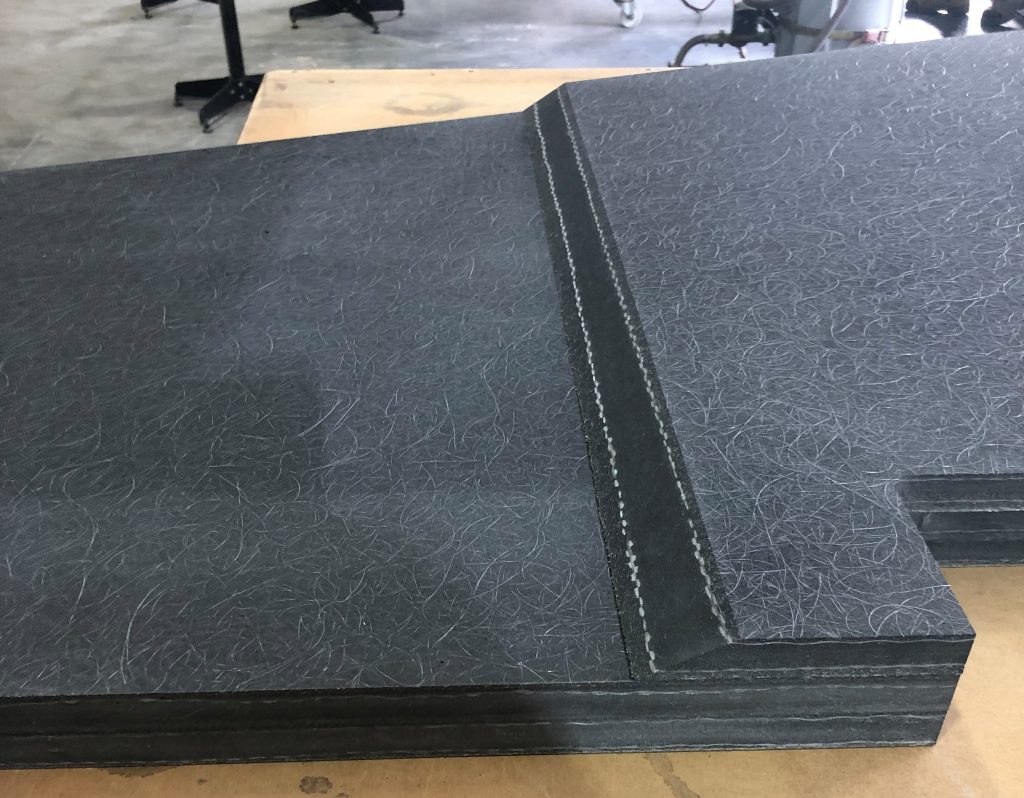

Composite Panels: Improving Automotive Efficiency

Posted on February 3, 2023

As technologies evolve to meet the constant demand for higher productivity, autoclave curing is progressively being replaced by alternative processing solutions such as compression moulding, standard infusion and high-pressure, fast-injection RTM. Epoxy resins, speciality core materials and high-performance reinforcements are now providing new structural solutions that will radically alter the way cars and other vehicles are designed and built.

Our in-mould coatings are used in the high-performance motor-sport industry, specifically V8 Supercars, to meet the high strength and toughness requirements. Manufacturers are increasingly focusing on alternative technologies and materials to optimise and adapt to the automotive industry’s requirements. That is where our expertise in the development of new and innovative composite processes comes into play.

The benefits of these new composite panels materials mean that cars can be made lighter, more efficient and with greater reliable than ever before. The possibilities are virtually endless as these composites can reduce weight, increase strength and durability, improve crash safety performance, reduce production costs and enable a wide range of vehicle configurations. In addition to this, our in-mould coatings allow us to create a range of finishes on the vehicle components that are both aesthetic and durable.

Our team of experienced engineers is dedicated to finding new and innovative solutions for automotive OEMs and their suppliers while working closely with them to ensure their needs in terms of quality, performance and cost are met. Our commitment to research, development and innovation has enabled us to stay at the forefront of the industry, delivering quality components that meet or exceed OEM requirements.

The automotive industry is constantly evolving and we are proud to be part of this evolution. We strive to remain ahead of the curve in our industry, offering the latest technology, materials and production processes to ensure that OEMs can get the best possible outcomes for their product. Our experienced team is dedicated to providing quality products and services, with a focus on customer service and satisfaction.

We have experience in the design and manufacture of composite panels material for refrigerated cars and trucks, emergency vehicles, utility vehicles and even campervans. Our dedication to quality materials, production processes and customer service has earned us the reputation of being a leader in our field.

ATL Composites is a leading supplier in Australia of advanced composite boards, materials and engineering for the construction of high-performance, lightweight structures for the marine, automotive, architectural, civil and industrial tooling markets. Get in touch with us today to learn more about our products and services!

TANK Rolls out for Double Duty

Posted on December 20, 2022

Meet us at METS 2022

Posted on September 19, 2022

Celebrating 40 years of Innovation in Composites

Posted on March 23, 2020

ATL Composites is celebrating 40 years of operations, supplying innovative coposite products to the marine, automotive, industrial and construction industries in Australia and around the world.

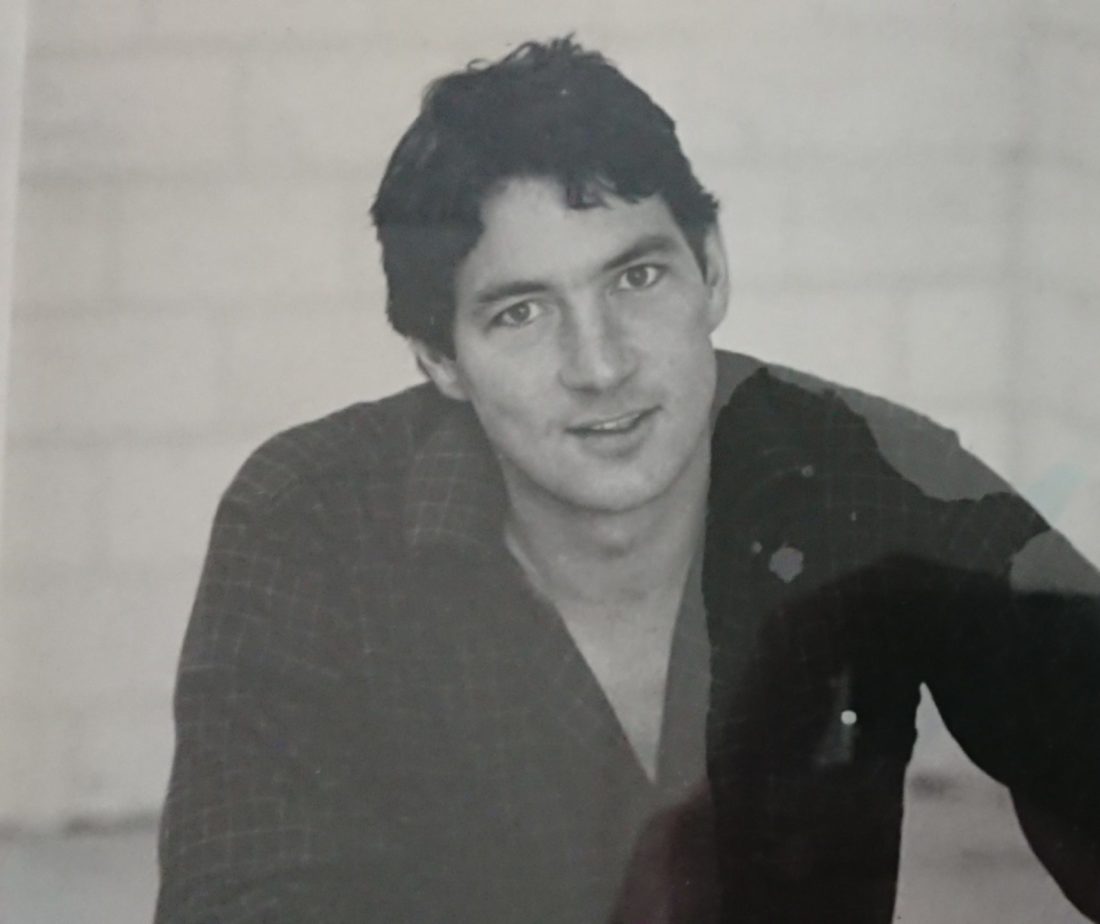

Arnie Duckworth early 80’s

Paying tribute to the vision of founder, Arnie Duckworth, who established the business in New Zealand in 1977, and the efforts, expertise and ingenuity contributed by ATL staff over the decades, Director Nicholas Cossich said “Without question, 40 years would have been impossible without the dedication, hard work and skill of our past and present talented staff who are very much looking forward to the future challenges and opportunities that our dynamic industry always presents.”

Mr Cossich also honoured the support and collaboration of ATL’s valued clients. “Success to date would not have been achieved without the firm support of our valued clients, distributors, dealers, colleagues, engineers, designers and naval architects to whom we are exceedingly grateful.”

The origins of the company are proudly in boat building, in the late 70s when Mr Duckworth, an avid sailor, relocated to NZ after a period working for the legendary Gougeon Brothers Inc in the US.

The Gougeons had developed the WEST SYSTEM epoxy system, that was revolutionising timber boat construction, by stabilising the moisture content of the wood. Back in the boat building powerhouse of NZ, Mr Duckworth observed a market for epoxy products to supply to the burgeoning marine industry, manufacturing WEST SYSTEM epoxy products under licence to Gougeon Brothers for the Asia Pacific region.

The decade of the 2000s were marked by an expanding market for multihull construction by both professional and amateur builders, whose designs were specified around the DuFLEX Building System, and the ATL used its knowledge and experience of composite materials to diversify into other markets where there is a demand for lighter, stronger, stiffer, more durable structures including automotive, architectural and surfing/sporting equipment and transportation applications.

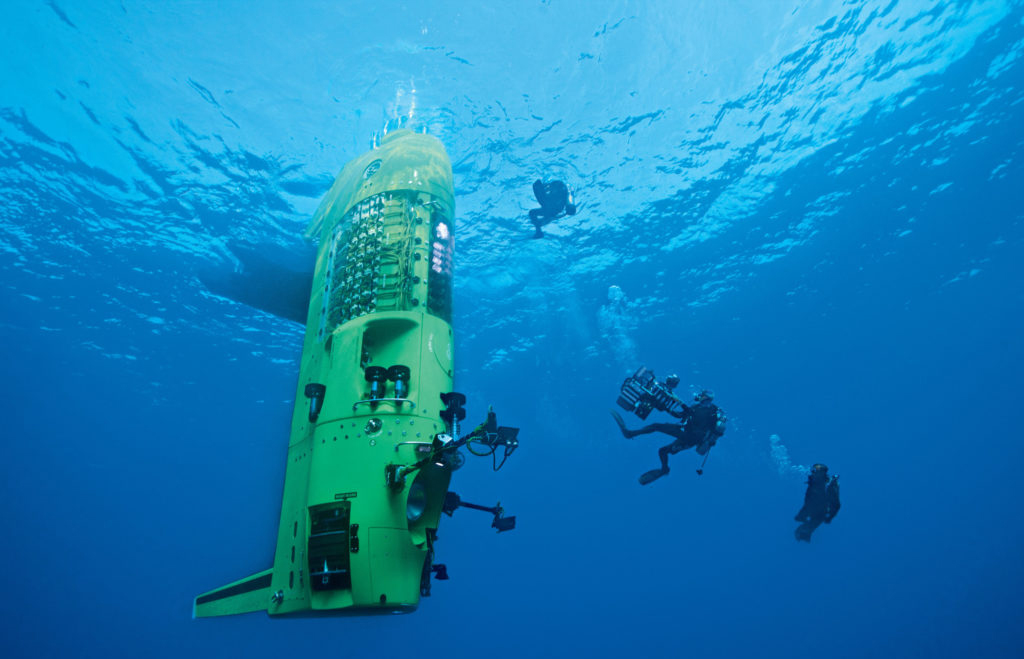

An outstanding achievement in 2012 was the development of a range of unique epoxy systems with extremely high compressive strength and toughness for the construction of James Cameron’s Deep Sea Challenger, a 7.3-metre deep diving submersible that made a record breaking 11 kilometre descent to the bottom of the Mariana Trench.A success which in essence thoroughly vindicated ATL’s certifications to ISO9001 and approvals under DNV-GL for delivering world-class product quality and performance.

“Enduring and close partnerships with leading International manufacturers including DIAB Group Sweden , Hawkeye Industries USA, Airtech Inc USA, and of course our very good friends at WEST SYSTEM Inc, USA, have been key to strengthening our position in existing markets, and expansion into emerging composite industries,” said Nicholas.

“We are also fortunate to be very well supported by a long established and extensive Distribution/Dealer network in every State and Territory of Australia and also throughout Asia in Thailand, Japan, Singapore, Vietnam, Malaysia, Indonesia, Philippines, Hong Kong, Papua New Guinea and Korea.”

Since 2012, ATL has enjoyed a fruitful joint venture partnership with MuH von der Linden of Wesel, Germany forming, vdL Composites GmbH to manufacture DuFLEX panels for the European market. During the successful showing at METS, Amsterdam in 2019, vdL appointed Distributors in Italy, Turkey and France to represent the DuFLEX and Featherlight composite panels in their regions.

ATL started 2020 with new products, a vision for the next decade and a commitment to build on the camaraderie and close bonds among their network of customers and colleagues worldwide.

Inga von der Linden, Director at vdL Composites, Germany sent her congratulations to ATL Composites for 40 years of innovation and excellence.

“We have been working together more than 30 years, since 2012 as distributor of DuFLEX and DuraKore panels and also for many years prior as colleagues and friends in the composite industry selling many similar product lines.

“We have had a shared stand at METS Amsterdam, also sharing houseboats, talking to each other monthly via Skype and seeing us at other industry events. That has made us much more than business partners. I love working with Lorraine and Nick and I wish for them many more successful years ahead.”

Ian Wright, third generation boat builder at Norman R. Wright & Sons, which itself commemorated 110 years in business, has been collaborating with ATL for around 30 years.

“There are almost too many yachts over the past three decades to mention by name,” said Ian.

“We met Arnie in 1982 and started working with ATL in 1987. ATL has always offered excellent support and service, especially on the technical side,” he recounted.

“In the past 15 years, they have contributed to the engineering on projects and we have been very grateful for their expertise.

“We have become extremely close, bonded by our mutual love of boats, cars, construction and aeronautical engineering. My son, an aerospace engineer, actually did work experience at ATL. They also helped build him a billycart when he was six years old.

“ATL supplied material and advice when I was building my family home at Wynnum – a green composite house we call the ‘eco-casa’. Lorraine and Nick are a great duo with exceptional skills and very complementary talents. We congratulate them on their 40-year milestone and all the best for many, many more.”

Tony Grainger, founder of Grainger Designs said “We’ve been with ATL Composites almost since the inception. From the 8m trimaran Dux Nuts (1987) through to our latest all carbon 42-foot custom trimaran Venom, and a host of catamaran and trimaran projects in between”.

“ATL have been with us on the journey with materials, state of the art laminating technology, DuFlex kits for our cruising cats, and engineering support.”

He continued: “There’s no digging needed to discover the success of ATL’s longevity. It’s cultural. The same faces are there year after year armed with technical know-how and a welcoming smile, whatever the questions. Congratulations and thanks to all the crew at ATL; and here’s hoping you guys are around for a lot more anniversaries.”

Jake Holloway, Product Manager at Shapers Australia, which supplies surfboard manufacturing products to leading surfboard shapers around the globe, was impressed with “ATL’s big 4-0”.

“That is an impressive innings to say the least, for any company in any industry,” he said. “In a highly competitive and rapidly changing environment the ability to maintain such a high level of product quality, customer service and innovation rings accolades to ATL Composites.

“What our company (Shapers Australia) really appreciate and find highly motivating is the relationship we have established with ATL. The culture of ATL is to work with customers as a team, a genuine partnership arrangement.

“It is through this partnership that ATL and Shapers Australia have been able to combine critical knowledge, share sensitive information and lead the world in the field of specialised epoxy solutions for the Surf Industry. The distribution achieved has been on a global scale and importantly the channels of communication are always open, always flowing and always looking towards the future. This mutual success is achieved through a partnership built on mutual trust and respect.

“From all the team at Shapers to all the team at ATL, Happy Birthday and a whopping big Thank you. Please raise your glasses and here’s to many great years ahead!”

Marinesports International in Victoria was among the original WEST SYSTEM Distributors appointed in Victoria. Director Andrew Morrison sent his best wishes for ATL’s milestone.

Marinesports International in Victoria was among the original WEST SYSTEM Distributors appointed in Victoria. Director Andrew Morrison sent his best wishes for ATL’s milestone.

“We established WEST SYSTEM with leading yacht chandleries and boat builders and in more recent times, several quality furniture manufacturers have come to realise the many benefits of using WEST SYSTEM products as a glue and for sealing timber.

“Over the past 40 years ATL Composites, under the guidance of Nicholas Cossich, Lorraine Murray and their team, have grown a reputation for excellent customer service offering quality products with technical support. We wish them every success for the future.”

Mr Cossich said the team at ATL was grateful for their customers’ loyalty and enthusiasm for ATL’s extensive range of products, commenting on their valuable input which has spurred product development and enhancements.

He said ATL is energised by attaining the 40-year marker and has no intention of resting on their laurels.

“We will continue to push the boundaries of material performance through our active research and development programs, and are looking to expand and improve our materials and technical proficiency in numerous aspects of cosmetic finishing, thermal ranges, fire-resistance and sustainability.

“Important new growth markets include defence, automotive, architectural and civil which are now leveraging our solid foundation of expertise and technology developed over decades in our key marine business.

“Our significant, long-standing international and domestic supplier relationships will continue to allow us to complement our own product ranges by offering world leading advanced composite materials to the Australasian market.”

METS yields Global Rewards

Posted on December 18, 2019

ATL Composites is pleased to announce agreements with new European distributors as a result of exhibiting at this year’s METSTRADE Amsterdam in November, the company’s seventh show with joint venture partners vdL Composites GmbH.

“We have established Distributors for our DuFLEX and Featherlight composite panels in France, Turkey and Italy,” confirmed Inga von der Linden, Director at vdL Composites, based in Wesel, Germany.

“They are the WEST SYSTEM distributors for those countries, and consequently, we have had relationships with their companies through the WEST SYSTEM network. But it was through exhibiting at METS that we met face to face and decided to work together.”

The new DuFlex and Featherlight distributors are Etap Marine, Istanbul, Directeck in Aubiere, France and WS Marine S.r.L. in Genova, Italy. “They are extremely well placed in key markets to supply some of the world’s premium boat builders,” added Lorraine Murray, Director at ATL Composites. “We are looking forward to more vessels coming on to the global market with the quality DuFlex/Foam and Featherlight panel systems for light-weight, strength and durability.”

The new distributors will stock a mixture of DuFLEX/Foam and Featherlight panels in various thicknesses and with single and double layers of e-fibreglass skins to service their local customers. They will also be in a position to offer custom panels including full sized component packs, for one-off projects and/or for their local production builders, produced to specifications by vdL Composites GmbH, which is based in Germany.

“These custom panels could also include panels with high density inserts for hardware installations which were of great interest to many of the professional boat builders who visited our stand at METS,” added Lorraine.

METS 2019 was an extremely successful show for ATL Composites.

“This was our seventh consecutive year exhibiting with vdL Composites GmbH and the most fruitful,” said Lorraine. “Australian brands and businesses enjoy great respect for our ingenuity, quality and proactive approach to tailoring solutions to every customer’s unique requirements.”

More at www.atlcomposites.com.au

DuFLEX: Aussie ingenuity on show at METS

Posted on October 14, 2019

ATL Composites and their European joint venture company, vdL Composites will attend this year’s METSTRADE Show in Amsterdam, 19 to 21 November, exhibiting the DuFLEX panel building system, developed in Australia and now industry standard for boat builders the world-over.

“METS is the world’s largest trade exhibition of marine equipment, materials and systems,” said Lorraine Murray, Director at ATL Composites, based on Queensland’s Gold Coast.

“It’s important to connect with our customers and our partners in Europe and show them the innovative ways DuFLEX can be used in boat building, saving production time and delivering lighter weight, stronger boats.”

Inga von der Linden at vdL Composites said “We attend METS because we meet the international industry there and we can show them the DuFLEX products in reality.

“Existing customers can also visit our stand and see new developments, network with colleagues and experience innovations from the global marine market.”

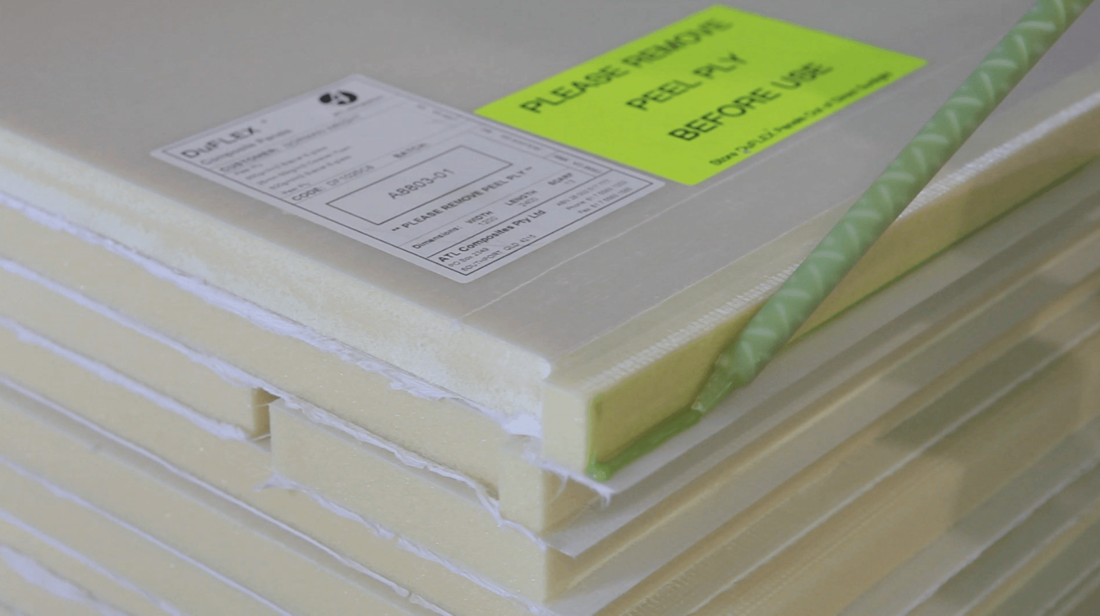

Developed in Australia by ATL Composites, DuFLEX panels are available with a range of lightweight, high-strength core materials that are laminated with a high-performance, specially formulated, epoxy resin and can be reinforced with multi-axial E-fibreglass or carbon fibre.

DuFLEX panels have become an industry standard for composite boat construction and the system is specified by leading designers around the world for the construction of pleasure, performance and commercial craft.

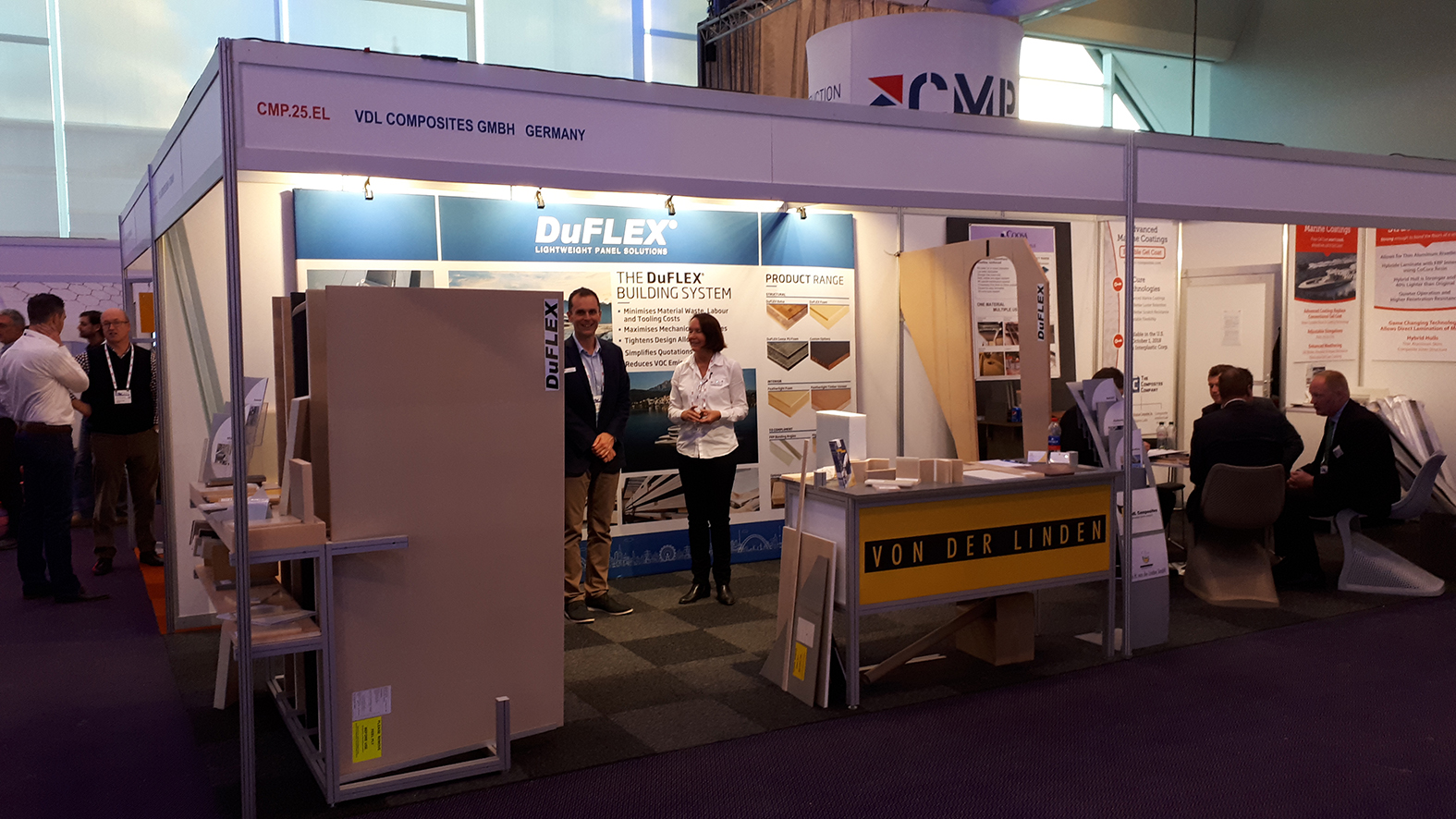

In 2012, ATL Composites and MuH von der Linden GmbH of Wesel, Germany, formed a joint venture company, known as vdL Composites GmbH to produce DuFLEX® composite panels for the European market.

Since then, the DuFLEX range has been available to professional boat-builders and designers throughout Europe, with local supply and experienced technical support provided by the Technical Team at vdL Composites.

Growing demand for the DuFLEX panels has led to an ever-increasing European customer base and the further development of options for customers.

Business secured directly from last year’s METS includes supplying DuFLEX for interior fitouts for ITA Catamarans and projects for Gunboat, Baltic Yachts and Nautor’s Swan.

As Inga explained “The Gunboat 68 used DuFLEX for interior panels for ceilings and cladding. Delivered as full-sized parts, the DuFLEX panels were cored with DIAB Divinycell H80 foam, and reinforced with several orientations of E-Fibreglass and/or Carbon Fibre to provide a combination of stiffness and strength. Vdl Composites also supplied 42mm and 84mm FRP Bonding Angles to provide a quick and effective way to make right angle joints between the panels.

“Iconic builder, Nautor’s Swan contacted us as a result of the referral from their neighbours, Baltic Yachts, who demonstrated the panels,” Inga continued.

Jan Vidjeskog at Baltic yachts said “DuFLEX panels are cured to our demands and have a good and even quality which make them easy and cost-effective to use.”

The vdL Technical Team will be available at METS to introduce you to The DuFLEX Building System, and to discuss your specific design and fabrication requirements.

vdL Composites will exhibit at booth CMP.25.EL in the Construction Material Pavilion.

More information at www.duflex.com.au and www.vdlcomposites.com

Visit Us at Sanctuary Cove International Boat Show 2018

Sanctuary Cove International Boat Show 2018

Posted on May 29, 2018

ATL Composites will be exhibiting at Booth #314 IN THE SUPERYACHT & MARINE PAVILION at this year’s Sanctuary Cove International Boat Show from Thursday May 24th thru Sunday May 27th.

“We are really looking forward to this year’s 30th Anniversary Show,” says Lorraine Murray, Director at ATL. “As a leading supplier of advanced composite materials and engineering to the marine industry for 38 years, we continue to look for ways to improve our products and services, and enjoy the opportunity to discuss and suggest solutions for specific projects with customers at the show.”

This year ATL will be displaying products specifically developed for the Marine Industry including the Six10 Structural Adhesive from the internationally recognised WEST SYSTEM epoxy range and DIAB’s Divinycell Structural Cores which have a proven industry history and are the choice for naval architects and manufacturers worldwide.

We are also show-casing two outstanding projects that were built with our DuFLEX and Featherlight composite panels – Kato the G-Force 2000 Speciale and Barcoo Drift, the 14m Roger Hill Power Catamaran.

Please visit our stand to meet our experienced Technical Team and to discuss how our products can work for you.