It’s a TANK …… 13.9m Roger Hill Mono destined to turn heads!

Roger Hill 12m Design takes shape with DuFLEX Composite Panels

Celebrating 10 years – Bonded in Composites

Noosa Cruiser 750 Unveiled

DUFLEX underlies New Generation Charter Cat

NEW Noosa Cruiser Incorporates DuFLEX Strip

DuFLEX the Key to Speed and Stability

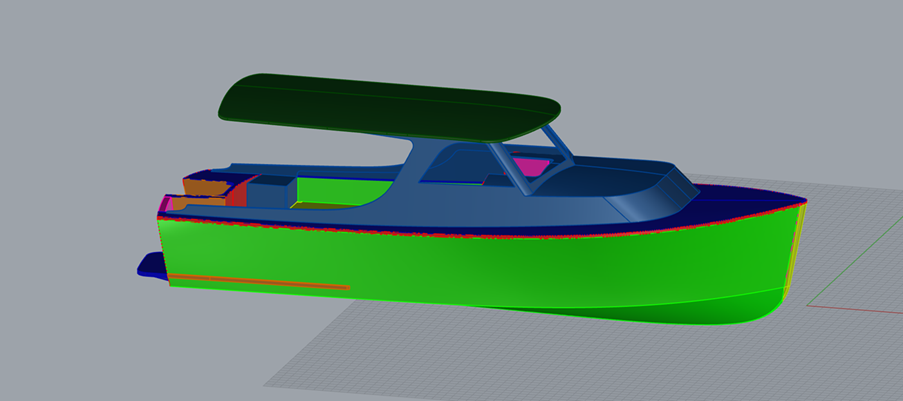

ATL Composites has supplied DuFLEX Composite panels and KINETIX high performance epoxy systems for the latest designs from Norman R. Wright & Sons for two new custom designed Pilot Boats for PNG Ports Corporation.

“Siabo” is the first boat to hit the water from Wrights featuring their all-new Extra Long Waterline (XLW Class) design, which offers optimum seakeeping and efficiency in all sea conditions and speeds in excess of 30 knots.

Norman R. Wright & Sons was one of 10 companies to tender for the first of a fleet of 14.2-metre pilot craft.

The DuFLEX Building System was used for the entire vessel construction, including hull shell, frames, bulkheads, deck and superstructure. Panels were supplied as full-sized components and offered significant structural weight savings over infusion and other traditional methods, as well as eliminating the substantial costs associated with moulding.

Working with ATL Composites, Wright’s Naval Architects and Master Tradesmen integrated unique composite construction, combining resin-infused and pressed GRP cored panels with DNV-GL approval.

The design allows for a reduced centre of gravity for superior stability enhancing pilot safety when alongside ships, along with wide, flush, uninterrupted side decks around the entire vessel for optimum safety.

The two new boats are the first in what is expected to be a fleet catering to the growing ports, cargo and liquid natural gas infrastructure in Port Moresby and the 21 other surrounding PNG ports that they service.

PNG Ports Corporation visited Wright’s headquarters at Rivergate Marina & Shipyard, Brisbane and trialled a comparable vessel.

“They were impressed with our 110-year history, our factory and our history of support on similar fleets in North Queensland,” said Tony Riek, Managing Director.

The 14.2-metre design is customised specifically to the needs of PNG Ports Corp designs and is based on an evolution of Wrights’ highly successful Skirmish Class Pilot Boats which draw on over 80 years of Pilot Boat design and building expertise.

“Pilot Boats are a part of our DNA,” explained Tony. “We designed and built our first in 1935 and since then designed and built some of the sturdiest craft seen, in some of the harshest Australian waterways and beyond.

“The quality of our boats means many are still in continuous service after decades of operation. There are Pilot Boats still in operation which we built in 1993. We have a team of highly skilled and qualified naval architects and boat builders using the latest technology, processes and high-tech materials.”

ATL Composites engineered the vessel to meet DNV-GL: 1A HSLC R2 CREW, and worked closely with Adam Evripidou, Tony Riek and the Wrights’ team on developing and optimising build techniques.

DuFLEX Composite Panels reduce construction time and optimise structural weight in the production of light weight composite structures. Using DuFlex panels in boat construction avoids time-consuming laminating, coring and vacuum bagging steps normally required to fabricate high performance composites, and material waste, labour and tooling costs are greatly reduced

More information at www.duflex.com.au

More information at www.duflex.com.au

Video of the boat in action: https://www.youtube.com/watch?v=g-ZpYgBPZ5A

Light, strong, fast and versatile, the Noosa 7 is turning heads and winning hearts.

Pre-Fab Perfection

Feature-filled power cat AYANA breaks New Ground in Charter

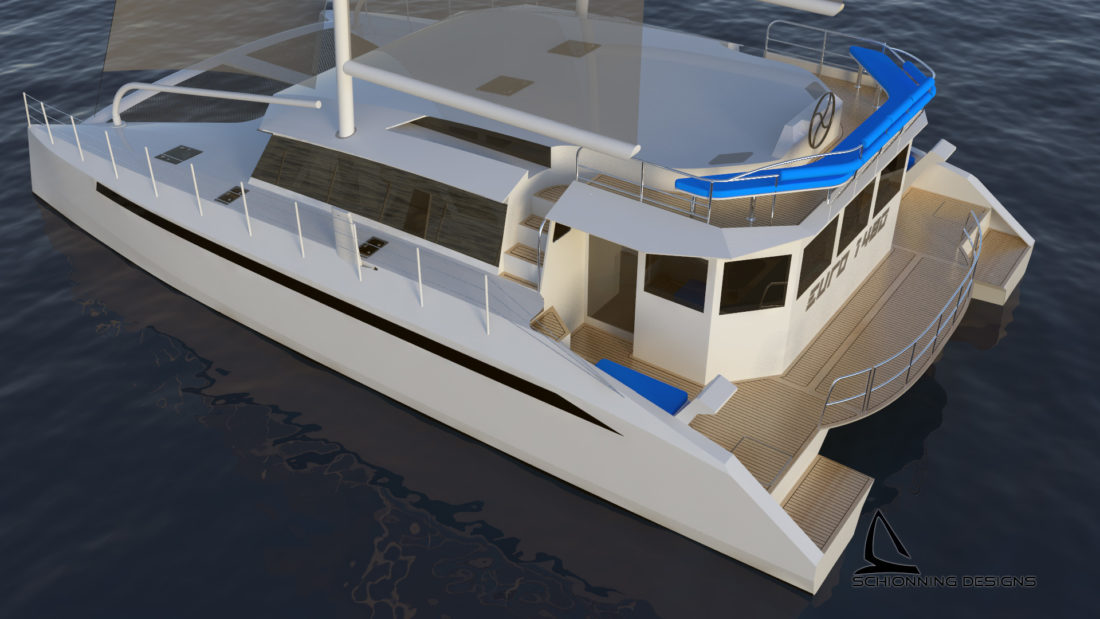

The latest Roger Hill-designed vessel, the 14-metre power catamaran called “AYANA”, has emerged from production at Noosa Marine and is now stored at The Boat Works, awaiting delivery to her discerning owners who plan to cruise from the Gold Coast back to their home waters of WA.

The fully-custom designed and built power cat is replete with unique features befitting a luxurious liveaboard vessel. With her planing hull, AYANA was built to survey with the intention of offering day charters cruising Rottnest, Margaret River and the Swan River.

As Julian Griffiths, Director at Noosa Marine explains: “AYANA weighs around 12.8 tonnes and has loads of extras. Her owner is an experienced boatie and wanted the works.”

AYANA is a spacious three-cabin multihull conceived for day charter, with a massive, versatile cockpit for entertaining or angling, which flows into the large saloon, also decked out for socialising with dinette, galley, AV and large windows for panoramic views. The enclosed flybridge features the helm and an L-shaped lounge and dining table, while the aft deck is fitted with a davit for the vessel’s tender.

Designer Roger Hill said the list of ‘must haves’ was daunting for him as a designer and for the team at Noosa Marine.

“From my perspective, the challenges involved weight control more than anything else. AYANA is a 14-metre superyacht. It probably has more fridges and freezers than any other 14-metre afloat!

“There is no such thing as a boat that is not some form of resolved compromise. But this boat is probably as close to what the owners would say has everything they want in a 14-metre package and from my point of view the biggest compromise will be the performance of the planing hull, which will still achieve around 28 knots.”

According to Roger, building to survey requires more structural material and more safety details, which results in extra weight and additional costs of around 20 percent.

“This boat was built to the highest standard of survey in Australia so it is at the top end of the spectrum for cost and compliance,” adds Roger.

From briefing to completion, construction took just 13 months. The Noosa Marine production team comprised Julian, Max, two apprentices and a labourer.

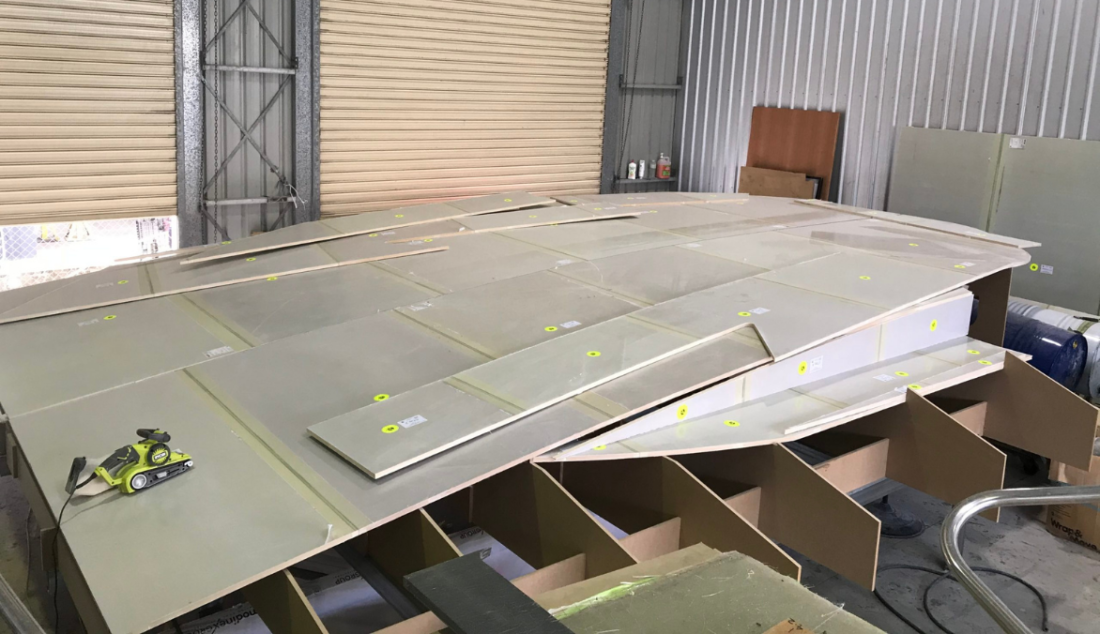

Key to their efficiency was the use of the pre-cut DuFLEX panel system from ATL Composites.

Other DuFlex panels in AYANA were cored with Divinycell’s H80, an industry standard for marine projects and ATL’s Featherlight Marine Interior panels combined Divinycell H60 core with 600gm double bias laminates.

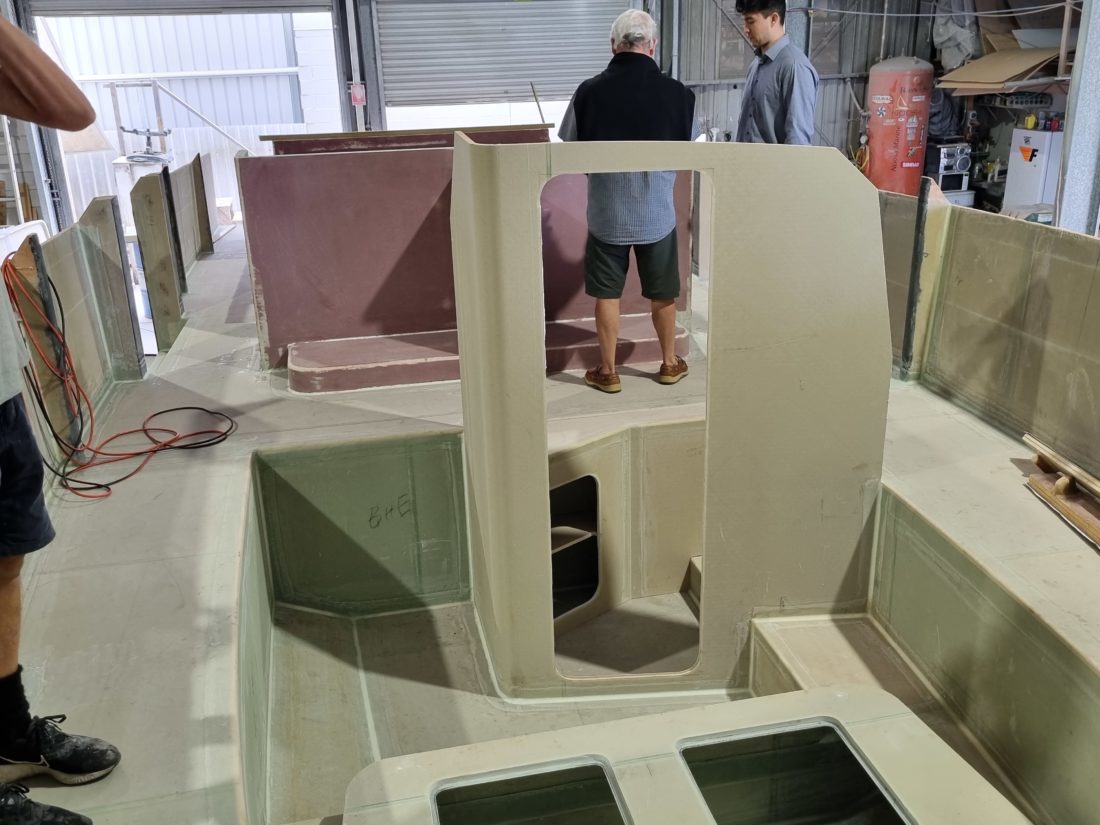

All components for the build, from temporary framing to structural hull sections, bulkheads through to the interior fit-out for AYANA were digitised from design files and nested to optimise the number of panels required for the project that were with ATL’s proprietary Z-Joint for joining and subsequent quick assembly.

“DuFLEX is incredible for saving time and reducing weight onboard,” Julian attests. “DuFlex offers builders a very high-quality panel and very precise accuracy, and for the client, an assurance of structural integrity.”

Roger agrees, stating: “Using the ATL Composites DuFlex panel system is a great way to build a boat particularly when it is embraced so well by this builder. Personally, I really appreciate the service and help that the team at ATL offers me as a designer. Their back-up and support are great.”